WHAT IS SILAGE?

Corn, sorghum, triticale, sunflower, alfalfa etc. It is a juicy, delicious, nutritious and economical roughage obtained by harvesting the forage plants at 60-70% moisture level, mincing them in 2-4 cm dimensions, compacting and storing them in closed environments called silo, and fermenting by lactic acid bacteria.

WHAT ARE THE BENEFITS OF SILAGE?

1- Silage is a juicy, delicious and nutritious roughage and meets the green fodder needs of animals, especially in farms that are not possible with grazing in winter or where animals are kept indoors in summer and winter.

2- In the method of preserving roughages by drying, the most valuable parts of the plant, such as leaves and flowers, which occur during the drying, baling, transportation, storage and feeding stages, are eliminated in silage production.

3- When green fodder is silaged, lactic acid is formed in the silage. Lactic acid attracts animals due to its smell, aroma and taste, and animals consume silage more enthusiastically and fondly.

4- Silage facilitates the digestion of other roughages and increases the rate of feed utilization.

5- There is a visible increase in meat and milk yield of animals fed with silage. Increase in milk starts on the 5th day, and on the 25th day in fattening.

6- Although silage is roughage, it is closer to concentrate feed (factory feed) in terms of energy, protein, vitamin and mineral balance rather than roughage. For this reason, the need for concentrated feed of animals fed silage decreases by 80%. This reduces feeding costs.

7- Since the silage is moist, it does not have a fire hazard as in dry grass, more silage can be stored in the same volume than dry grass. While 700-1,000 kg of silage can be stored in a volume of 1 m3, dry roughages can be stored in the same volume of 250-300 kg.

8- A quality made silage can be stored for years (3 - 5 years) without any decrease in its quality and nutritional value, unless it is airy,

9- Silage making is suitable for mechanical agriculture at every stage from planting to harvesting, from packaging to feeding. Therefore, the labor requirement is less.

10- The cost of silage is 50% cheaper than other dry roughage (grass, alfalfa, straw, etc.) and 80% cheaper than concentrated feed.

WHAT ARE THE MATTERS TO BE CONSIDERED IN SILAGE MAKING?

As mentioned above, silage is a feed that has many advantages over other feeds. However, making and using silage is a process that requires being conscious. Since the silage is moist, an incorrect application may cause the product to deteriorate, be out of use or not to see the expected benefits from the product. Points to be considered in silage making

1- Harvest (shape) period of the product; The plant to be silaged should be harvested in the most appropriate maturity period. The early form causes the dry matter level of the product to remain low and the late form causes the woody structure of the product to increase and the quality of the silage to decrease.

2- The humidity of the plant; The humidity of the plant to be silaged should be around 30-40% during the harvest period. If the humidity is too high, silo water will exit, this is a loss. If the humidity is low, it will be difficult for the product to ferment.

3- Minced meat size; The plant to be silaged should be chopped in 2-4 cm dimensions. If it is minced in smaller sizes, the silo water output increases, the digestion time is shortened in animals, the benefit of the animal from silage decreases. If the shores are larger, the product will not be well compacted, air will remain in the product, fermentation will not be good and the quality of the silage will decrease.

4- Compression; The plant to be silaged should be well compacted in the silo. With the compression, there is no air in the silage, the activity of the oxygen-breathing bacteria that try to spoil the silage stops, instead, the oxygen-free bacteria respiration that allows fermentation begins. Thus, it is fermented.

5- Silage should not get air; The silo should be closed in a way that it will not take air and the contact of the silage with the outside air should be completely cut off. As stated above, if the silage does not take in air, oxygen-free breathing bacteria work, the silage is fermented and kept intact for years. If the silage gets air, oxygen-breathing bacteria work, the plant first gets hot and then molds. Thus, silage may become unreadable.

6- Fermentation process; After the silage is filled into the silo, the fermentation process should be waited. In this process, bacteria breathing without oxygen (LAB) break down the sugar in the plant for silage, lactic acid emerges, lactic acid silage yeasts and quality silage is produced. This process takes 20-60 days depending on the plant, the temperature of the air and the structure of the silo.

7- Conscious consumption: silage should be consumed consciously. In order to see the above-mentioned benefits, quality silage should be made, and the silage that meets the daily needs of the animals should be mixed with other roughages and fed to the animals.

As can be seen, silage making requires a conscious production from harvest period to minced meat size, from compression to silo, from fermentation to consumption. Silage making is a production chain. Failure to be made in a link of the chain may cause the silage to deteriorate, not to feed or to see the expected benefit from silage. In this case, how will the farmers who do not know the silage, have no land, the climate is not suitable for growing silage plants, do not have machinery equipment, and in short, do not have the infrastructure to make silage?

The answer to this question is; It is to make and use PACKAGED BALE SILAGE.

WHAT ARE THE BENEFITS OF MAKING PACKAGED BALE SILAGE?

Packaged bale silage is a production method that enables silage to be packaged, distributed and consumed throughout the country as it is packaged, where the land suitable for silage production, climate, machinery-equipment park and most importantly in places with knowledge and experience. With this method;

1- Even farmers who have never grown silage plants, have never seen a silage machine, and have not done silage all over the country can access quality silage and use it to feed their animals.

2- When all livestock farms use the silage made by this method, they can see all the benefits of the above-mentioned silage (decrease in cost, increase in meat and milk yield, etc.)

3- The excess silage that businesses buy but do not use can be stored for years without loss of nutrients.

4- With this method, silage trade starts. In regions with suitable land and climate and sufficient machinery and equipment parks, entrepreneurs can make packaged bale silage and send products to farmers in other disadvantaged regions.

5- Since silage bales are packaged separately, without spoiling the bales, silage bales can be opened and fed to animals as much as daily need.

6- Knowing, consuming and seeing the benefits of silage can be done in larger areas and in greater amounts. This situation decreases the feed cost of the livestock businesses and increases their productivity. As a result, animal husbandry in the country may reduce feed expenses, which are the biggest expense item.

WHAT KIND OF PRODUCTS CAN SILAGE BE PACKAGED?

In principle, all kinds of forage crops can be silaged and packaged. However, the most silaged plant in the world is corn. Corn is the most silaged plant for reasons such as high nutritional value, easy fermentation, easy cultivation, high amount of product per unit area, and being suitable for mechanical agriculture. In addition to corn, silage of sorghum, triticale, alfalfa and fresh sugar beet pulp (pulp) is made and packaged in large quantities. In addition to these products, industrial products such as all kinds of vegetable and fruit pulp, canning factory residues, barley pulp, wood chips, cotton, paper and plastic residues can also be packaged with these machines.

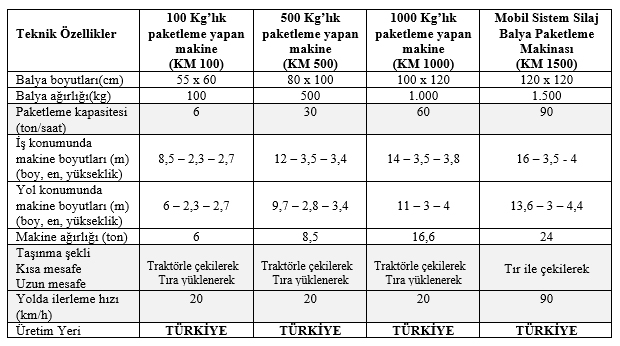

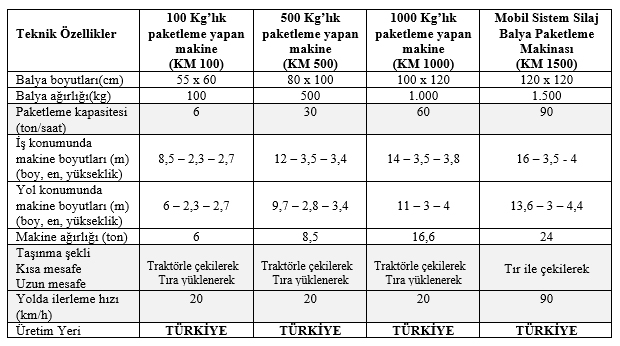

KOMSİLAJ BALE SILAGE PACKAGING MACHINES

Komdeğirmen Located brand with machines in the manufacturing sector since the year 1985, our company with KOMSİLAJ brand since 2010 began production of the first bale silage wrapping machines in Turkey. In a short period of 10 years, it has pioneered the birth and development of the silage packaging industry in Turkey and abroad with its KM-100, KM-500, KM-1.000 and KM-1.500 (Mobile System) models. The technical features of the bale silage packaging machines produced by KOMSİLAJ and the information about the silage bales they make are given below.

KOMSİLAJ WHAT ARE THE ADVANTAGES OF BALE SILAGE PACKAGING MACHINES?

Our company is the first company started the production of silage bale wrapping machines in Turkey. Komsilaj has produced the first bale silage packing machine and has been the pioneer of innovations in bale silage packing machines. Some of the features that make comsilage silage bale packaging machines stand out from other brands in the sector.

1- Initial purchase price; The initial purchase price of comsilage, silage bale packaging machines is 50% cheaper than equivalent machines abroad.

2- Required energy source: While silage bale packaging machines produced abroad use tractor power take-off and diesel fuel energy, Komsilaj silage bale packaging machines work with 380 volts of electrical energy. This reduces the energy cost by 80%. In addition, 380 volts of electrical energy is produced for the operation of the machine with the alternator, which is offered as an option on the bale silage packaging machines and operates with the power of the tractor tail shaft, where there is no 380 volt electrical energy, and the machines operate uninterrupted in every environment with low energy cost.

3- The quality of the material used: Each of the mechanical, hydraulic, electrical, electronic and pneumatic materials used in the production of comsilage silage baler packaging machines are selected from world-renowned products that are prominent in their field, and the highest quality machines are produced by giving priority not to low cost but to high quality.

4- Ease of use; Komsilage silage bale packaging machines do the feeding, bale making, net and stretch wrapping processes completely automatically and work without the need for human intervention. From the machine control panel, production parameters such as bale density, stretch and net wrapping number, feeding speed are digitally adjusted according to the product to be packed and the machine does the silage packaging itself without the need for human labor.

5- Spare parts and service: Komsilaj keeps all spare parts of the bale silage packaging machines in its stocks. 24/7 uninterrupted service is provided at home and abroad with 2 separate service teams.

6- Possibility of remote intervention: Compsilage silage bale packaging machines notify the operator in written and audible warning method of possible malfunctions that may occur on the machine through the fault notification section on the control panel. Wherever the machine is located in the world, it can be connected to the internet connection remotely to intervene in the setting and production parameters of the machine. This situation allows many malfunctions other than mechanical malfunctions to be eliminated immediately and on site.

As Kom Mill;

Why US?

Over 36 Years Of Experience

- The winding system of our machine is proportional valve and hydraulic systems.

- Because the winding system works with hydraulic system, it is faster and more durable, stretch the tension and increase the number of bales.

- The machine body cover system is proportional valve, and it works with double stage variable speed. It works much faster than systems that use flat valves.

- Our fishnet system works with hydromotor.

- We use double felt in the housing bearing system.

- This system provides more efficient performance to run the machine faster.

- All chains and Gears of the machine have automatic lubrication application.

-Possible failures are prevented by automatic lubrication application.

-Machines without this system often experience failures and the chain Life is shortened. - Automatic lubrication is also applied in all ball bearing systems of our machine.

- Because our machine works with proportional system, it has double hydraulic pump and double cooler system.

- The Body Gears of our machine are locked bushings and the gears are centered in a stable and healthy way to the relay shaft.

-Gears are much better quality and healthy compared to wedge system.

If your goal is quality; one day we will definitely meet.

About Us

Quick Link

Contact Us

Adress

Büyükkayacık OSB Mahallesi, 513 Nolu Sokak, İdari Bina NO:11

SELÇUKLU/KONYA Telephone: +90 (532) 400 29 61 / +90 (553) 294 68 55

Email: bilgi@komsilajmakine.com

Fax: 0 332 345 02 58

Büyükkayacık OSB Mahallesi, 513 Nolu Sokak, İdari Bina NO:11

SELÇUKLU/KONYA Telephone: +90 (532) 400 29 61 / +90 (553) 294 68 55

Email: bilgi@komsilajmakine.com

Fax: 0 332 345 02 58